iTAM

intelligent Transmission Asset Monitor

Utilities have made significant investments in substation and transmission assets. Substations are critical for reliable operation of power systems and serving customer loads. Substation assets, such as transformers, circuit breakers, instrument transformers (Current Transformers (CT), Potential Transformers (PT), Coupling Capacitor Voltage Transformers (CCVT)) and Intelligent Electronic Devices (Relays, PMUs, DFRs), must operate properly for power system operations, grid reliability, and personnel safety. Failure of these assets could cause forced outages, personnel safety issues, switchyard equipment damage, power system reliability issues, etc. PMU data from PTs, CTs, CCVTs, etc., can be used to monitor equipment signatures and identify anomalies that are precursors of potential equipment failure. Early warning, and timely intervention to repair or replace equipment before catastrophic failure will promote safety, reduce costs and prevent outages.

Intelligent Transmission Asset Monitor (iTAM) Platform uses advanced analytic methods to detect equipment malfunction and precursors to equipment failure. By monitoring signal signature anomalies iTAM can detect potential equipment malfunction and alert utility personnel in real-time to diagnose the malfunction and take appropriate actions to prevent equipment failure, customer outages and injury. It will also help avoid relay system mis-operation, equipment damage, forced outages, and safety hazards, and support calibration of Instrument Transformers (IT) & Intelligent Electronic Devices (IED).

iTAM provides unprecedented visibility into the status and health of secondary equipment, especially CTs, PTs and CCVTs, by using high-resolution (30 samples per second and above for 60 Hz systems and 25 samples per second and above for 50 Hz systems) synchrophasor data to monitor signatures and data patterns to identify anomalies. It enables utilities to use synchrophasors as a complement to existing asset health monitoring tools.

Introducing iTAM

- Failure Signals

- CCVT Failure Detection - Model Based Method

- CCVT Failure Detection - Data Driven Methods

- Architecture and Data Flow

Detection of Failure Signals

- iTAM can analyze equipment signatures and alert relevant personnel to facilitate pre-emptive checking, repairs and other actions to prevent potential catastrophic failures. iTAM offers the following capability to detect transmission equipment failure in substations and alert operators via alarms:

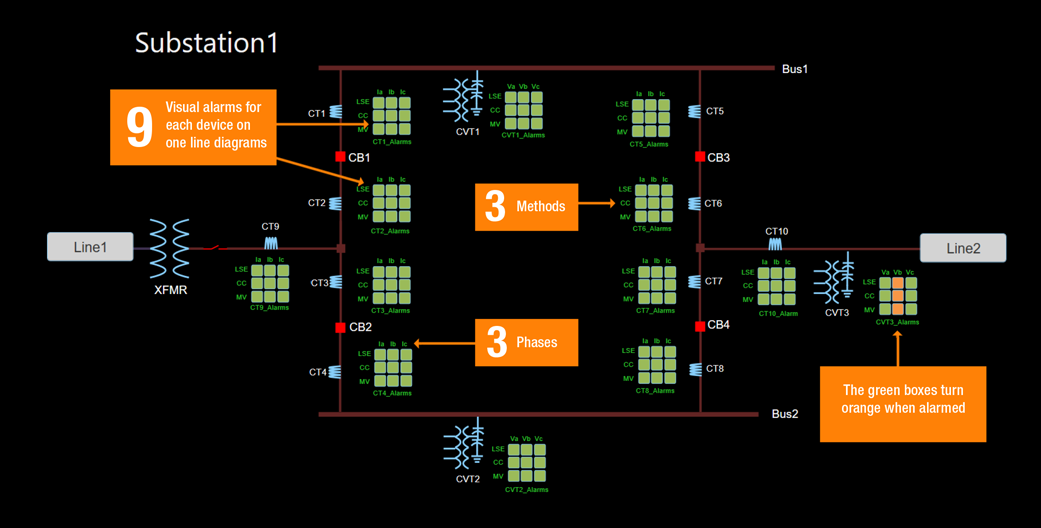

- • Monitoring of all three phases of each equipment

- • Failure detection using three different methods - one model based on two data-driven methods

- • Alarm panel with nine alarms for each equipment - each of 3 phases with 3 methods

- • Alarms visualized in real time on one-line diagrams, alarm panels and on dashboard that included alarm history

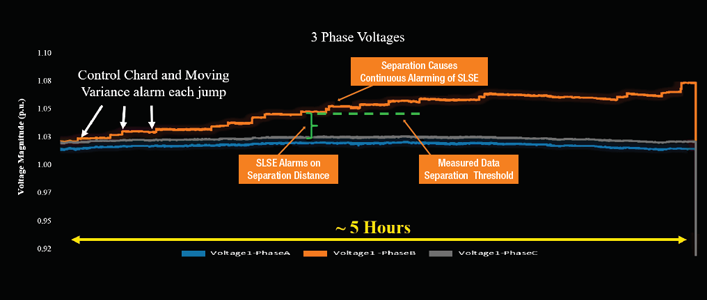

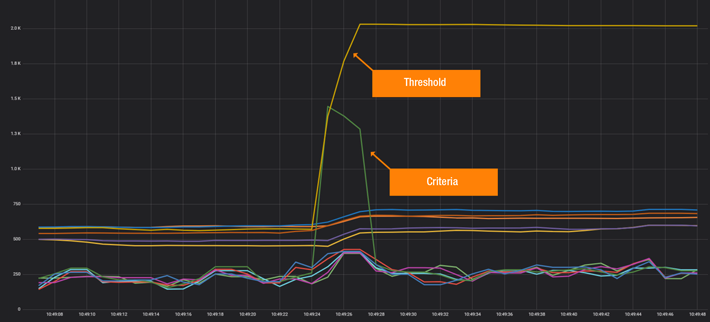

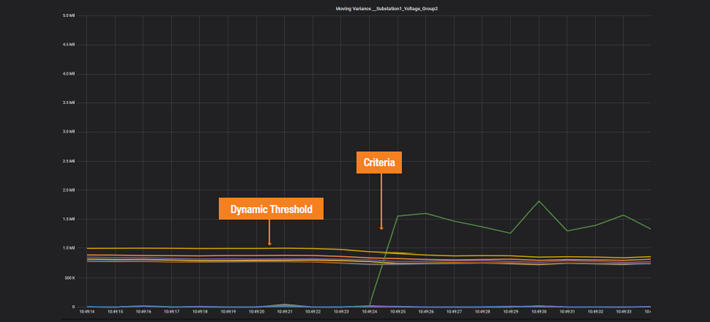

The model-based method uses Substation Linear State Estimation (SLSE) and compares the SLSE estimated data to the measured PMU data. This method ignores system events such as line faults and tripped breakers and only detects local events/anomalous data that may indicate equipment malfunction. The data driven methods rely on statistical comparison of previous data in a time window to the latest data. When the latest data has an error and falls outside of what is expected given its history, an alarm will be triggered. The data driven methods cannot by themselves differentiate between system events that affect all the measuring devices, such as line faults and tripped breakers, and local events/anomalous data that effect very few measuring devices and may indicate hardware failure. Therefore, additional logic has been implemented to avoid alarming on system events.

Download the iTAM brochure

EPG has been pioneering the development and deployment of synchrophasor technologies since 2000 and helping reliability operations across all three interconnections (WECC, EI and ERCOT)

EPG has been pioneering the development and deployment of synchrophasor technologies since 2000 and helping reliability operations across all three interconnections (WECC, EI and ERCOT)

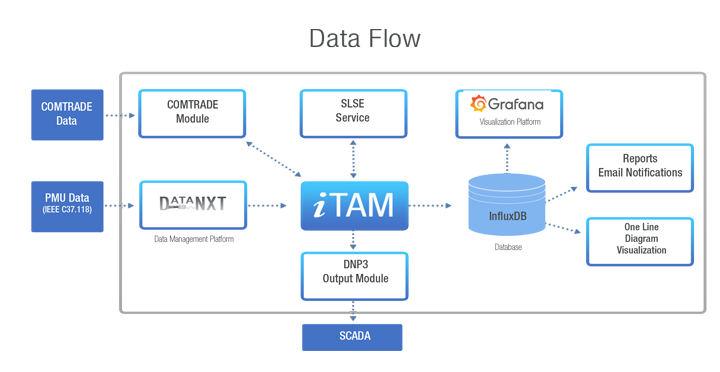

PMU data flows through DataNXT for conditioning before it is sent to the iTAM engine. iTAM is both an application and an application host. iTAM runs all the calculations for the data driven algorithms for anomaly detection. It hosts 4 applications: InfluxDB database, Grafana visualization platform, SLSE Engine, and DNP3 Module. The applications can be run locally at the substation(s) or from a centralized location such as the control center. Alarms can be sent to the EMS via industry standard protocols, such as DNP3. iTAM functions as follows. iTAM receives data from DataNXT and the data is stored in InfluxDB. iTAM hosts the SLSE that takes data from Influx DB, runs its calculations and sends them to InfluxDB. Separately, iTAM runs the data driven algorithms Control Chart and Moving Variance and adds the results to InfluxDB. Once all operations are performed on the data and the results are stored in InfluxDB, the results are displayed in Grafana. Alarms can be displayed in Grafana or on the One-Lines diagram. Flags and alarms can be sent to EMS using DNP3 Module.

PMU data flows through DataNXT for conditioning before it is sent to the iTAM engine. iTAM is both an application and an application host. iTAM runs all the calculations for the data driven algorithms for anomaly detection. It hosts 4 applications: InfluxDB database, Grafana visualization platform, SLSE Engine, and DNP3 Module. The applications can be run locally at the substation(s) or from a centralized location such as the control center. Alarms can be sent to the EMS via industry standard protocols, such as DNP3. iTAM functions as follows. iTAM receives data from DataNXT and the data is stored in InfluxDB. iTAM hosts the SLSE that takes data from Influx DB, runs its calculations and sends them to InfluxDB. Separately, iTAM runs the data driven algorithms Control Chart and Moving Variance and adds the results to InfluxDB. Once all operations are performed on the data and the results are stored in InfluxDB, the results are displayed in Grafana. Alarms can be displayed in Grafana or on the One-Lines diagram. Flags and alarms can be sent to EMS using DNP3 Module.