Menu

- Home

-

Products and Solutions

-

-

Industy Leaders

-

EPG has been pioneering the development and deployment of synchrophasor technologies since 2000 and helping reliability operations across all three interconnections (WECC, EI and ERCOT)

EPG has been pioneering the development and deployment of synchrophasor technologies since 2000 and helping reliability operations across all three interconnections (WECC, EI and ERCOT)

-

EPG Products

- intelligent Transmission Asset Monitor (iTAM)

- enhanced Grid Event Notifications System (eGENS)

- Real-Time Dynamics Monitoring System (RTDMS)

- Phasor Grid Dynamics Analyzer (PGDA)

- enhanced Phasor Data Concentrator (ePDC)

- Phasor Simulator for Operator Training (PSOT)

- enhanced Linear State Estimator (eLSE)

- PhasorSmart

- Automated Event Miner (AEM)

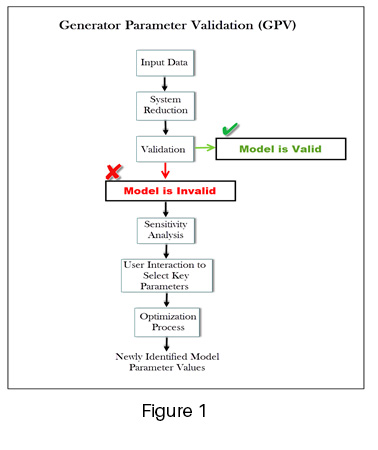

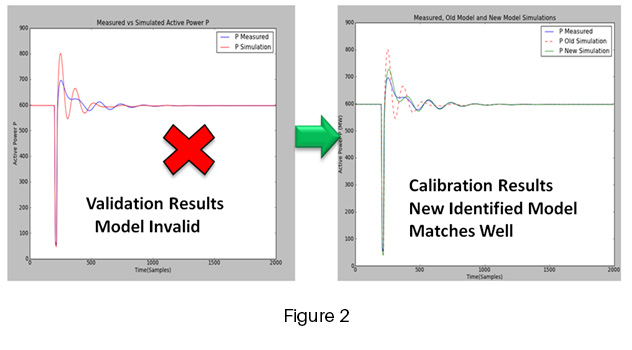

- Generator Model Validation (GMV)

- DataNXT

- PhasorNXT

- enhanced Phasor Data Extractor (ePDE)

- All Products

-

EPG Solutions

- Real Time Systems

- Analytics

- Data Management and Archiving

- Data Quality

-

-

- Projects and Services

- TRAINING

- SUCCESS STORIES

- About EPG